The Benefits of LGSF Manufacturer over Conventional Construction

The building industry is undergoing a major transition towards contemporary building methods that offer cost-effectiveness, sustainability, and efficiency. A technique that is becoming more and more popular is Light Gauge Steel Frame LGSF Manufacturer It is clear why is gaining traction as an alternative to traditional construction techniques when we examine its benefits.

LGSF Manufacturer: What is it?

Cold-formed steel is the main structural component used in .Utilizing prefabricated and on-site assembled steel frames, this technique is robust but lightweight. LGSF offers a contemporary, efficient approach to building, in contrast to conventional construction techniques that mainly rely on bricks, mortar, and concrete.

Construction Speed: Quicker Build Times

The speed at which can be completed is among its strongest features. Steel component prefabrication speeds up on-site assembly and consequently shortens the construction schedule overall. However, because materials like concrete require time to cure, conventional methods frequently take longer.

Saved Labor Expenses

Lower labor costs are a result of LGSF MANUFACTURER efficiency. Developers can save a lot of money by requiring fewer on-site personnel and shorter project durations. The labor-intensive procedures used in conventional construction are more expensive and take longer.

Sturdy and powerful

Excellent Integrity of Structure

The strong and long-lasting nature of LGSF structures is partly attributed to steel’s well-known high strength-to-weight ratio. These structures are more resistant to severe weather and seismic activity than their conventional counterparts. Particularly in regions vulnerable to earthquakes, brick and mortar buildings are more vulnerable to damage over time.

Durability

Termite infestations mold, and other common problems that afflict conventional buildings are not a problem for LGSF buildings. Because LGSF construction lasts longer and requires less maintenance, it ultimately offers better value for the money.

Powerful Efficiency

Improved insulation and energy efficiency are made possible by the accuracy of LGSF parts. Higher energy ratings and fewer energy expenses are possible for buildings built with LGSF techniques. This degree of thermal efficiency is a difficult feat for conventional building techniques LGSF MANUFACTURER.

Flexibility in Design: Architectural Liberty

When it comes to design flexibility, LGSF is superior to conventional construction. Steel frames’ lightweight construction permits more expansive open areas and LGSF MANUFACTURER creative architectural designs without the need for extra support columns. Because of its adaptability, LGSF is perfect for contemporary, visually beautiful structures.

Tailoring

A high degree of customization is possible by tailoring prefabricated LGSF components to particular design specifications. With traditional building techniques, where modifications can be expensive and time-consuming LGSF MANUFACTURER it is more difficult to accomplish this adaptability.

The cost-effectiveness; Reduced Materials Expenses

Although the initial cost of steel may be higher than that of other materials, LGSF MANUFACTURER typically has a lower overall cost. Notable savings are achieved through reduced labor costs, expedited build times, and minimal waste. Traditional building frequently has higher overall costs because it uses bulkier, less efficient materials.

Little to No Waste

The low waste that results from the precise manufacturing of LGSF components is guaranteed. The amount of extra material that usually arises from conventional construction is decreased because each piece is made to fit precisely. This efficiency reduces the environmental impact while simultaneously saving money.

Safety and Health Better Conditions for Work

Construction sites that use LGSF are typically safer and more regulated. There are fewer accidents and injuries because there is less construction activity on site when components are fabricated off-site. LGSF MANUFACTURER Workers are more at risk on traditional construction sites because of the heavy machinery and dangerous materials used there.

Fire Reticulation

Compared to wood-framed buildings LGSF MANUFACTURER uses non-combustible steel frames, which provide superior fire resistance. This feature lowers the possibility of damage from fire and increases occupant safety within the building worldwide, a plethora of accomplished projects attest to the benefits of From resident

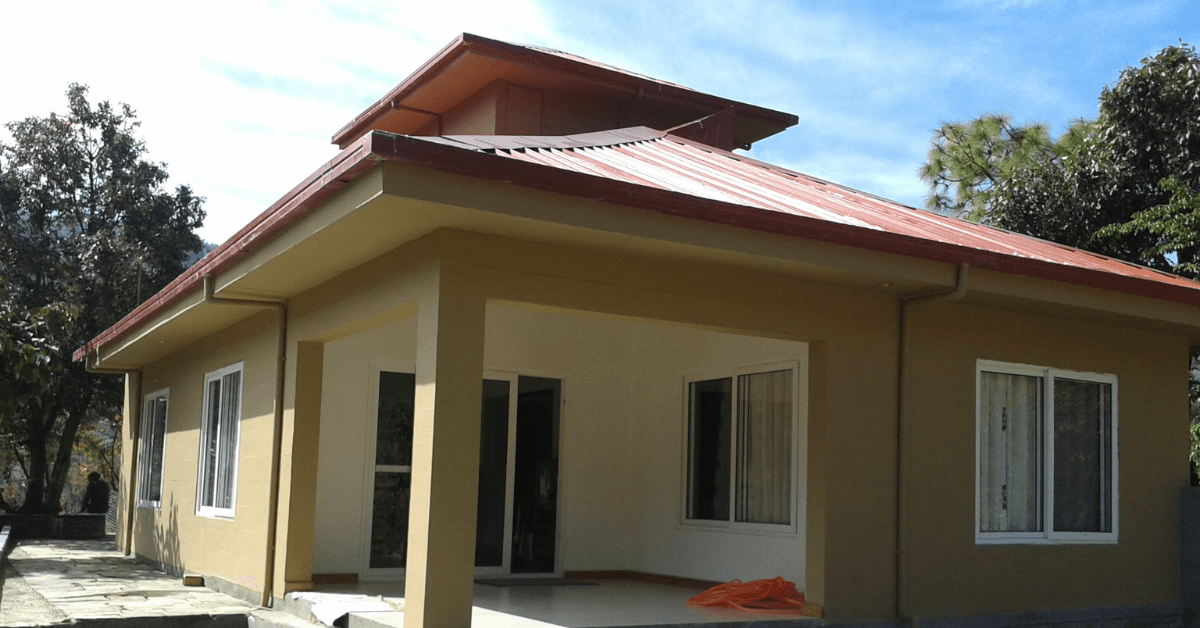

Experience LGSF’s fast builds, environmentally friendly materials, and exceptional structural integrity—the building of the future. With LGSF construction, you can wave goodbye to antiquated practices and welcome effectiveness, durability, and sustainability to commercial buildings, this method’s versatility and benefits are clear to see. For example, LGSF buildings have proven to perform

FAQs (Frequently Asked Questions)

Q1. LGSF MANUFACTURER: what is it?

A. A contemporary technique for constructing structures is called , and it makes use of cold-formed steel sections that are usually 1-3 mm thick.

Q2. What distinguishes traditional construction?

A. Steel frames are used in as opposed to more conventional materials like wood or concrete.

Q3. What benefits does LGSF MANUFACTURER have over traditional construction?

A. Faster construction times, increased durability, less maintenance, and better thermal performance are just a few benefits of

Q4. Is building an LGSF more expensive than building a conventional structure?

A. may initially cost a little more than conventional construction, but in the long run, it’s usually more economical due to the savings on energy and maintenance.

Q5.Is it possible to use LGSF MANUFACTURER for any type of building?

A. For a variety of building types, including commercial, industrial, and residential ones, is a feasible technique.

Q6. Is building with LGSF environmentally friendly?

A. Because steel is a highly recyclable material and LGSF MANUFACTURER produces less waste than conventional methods, it is indeed regarded as environmentally friendly.

Q7. Are LGSF structures just as sturdy as traditional ones?

A. More often than not, LGSF MANUFACTURER are made to be stronger and more durable than traditional building codes.

Q8. How long does an LGSF building last?

A. If properly maintained, LGSF MANUFACTURER should have a lifespan of at least 50 years, which is longer than that of conventional structures.

Q9. Is it possible to combine LGSF MANUFACTURER with other construction techniques?

A. Actually, combining with other methods ,LGSF MANUFACTURER like using concrete or wood, allows for the creation of hybrid structures that maximize the best qualities of each material.

Q10. Does LGSF MANUFACTURER have any restrictions?

A. Even though has many advantages, without additional engineering considerations, LGSF MANUFACTURER it might not be appropriate for buildings in high seismic zones or those needing very large clear spans.