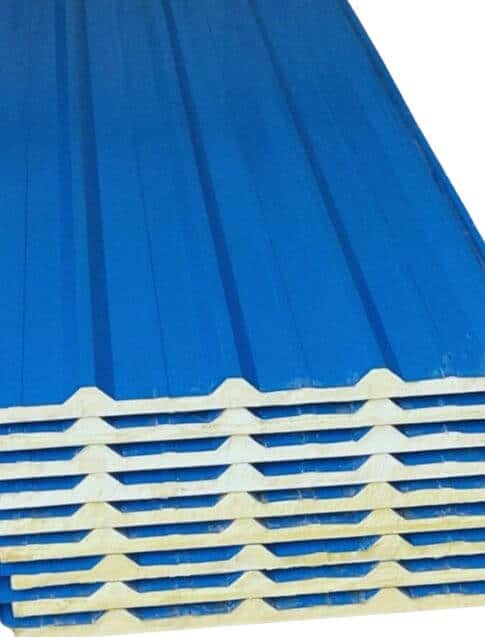

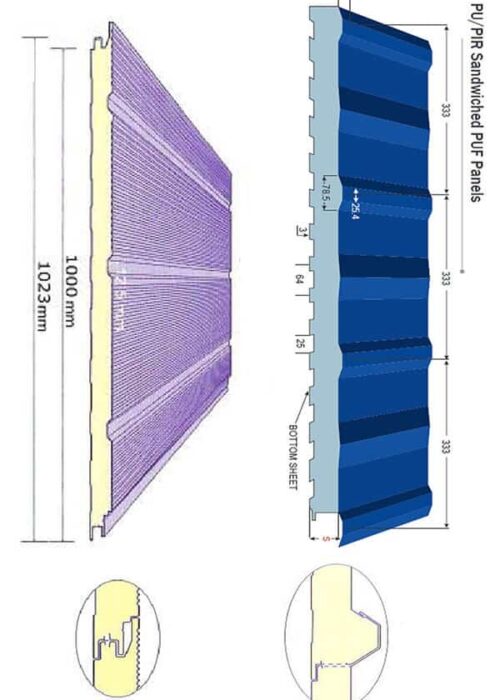

The development of PUF (Polyurethane Foam) panels throughout time has completely changed how modern building is done. PUF panels, which were first created in the middle of the 20th century, have advanced significantly and are now essential in many different building applications. Their remarkable thermal insulating qualities are one of the main factors promoting their broad use. PUF panels are being used more and more by architects and builders to satisfy the strict thermal performance criteria as concerns about sustainability and energy efficiency grow. Furthermore, PUF panels’ lightweight design makes them perfect for use in prefabricated building, allowing for quick assembly and cutting down on project completion times. Manufacturers have upgraded the production methods in response to technological advancements, producing panels with increased durability and structural integrity. PUF panels are now widely used in specialist constructions like cold storage facilities, clean rooms, and temperature-controlled conditions in addition to regular buildings. Beyond its ability to insulate, PUF panels are also highly effective at soundproofing, which improves occupant comfort in both residential and commercial settings. Furthermore, improvements in fire-retardant coatings have improved PUF panels’ safety profile and allayed worries about their flammability. PUF panels are still evolving as a result of continuous research and development, with advancements aimed at improving affordability, sustainability, and performance.

Consequently, solar panels continue to be at the forefront of contemporary building, providing an attractive answer to the changing demands of the sector while also making a positive impact on environmental stewardship and energy saving.